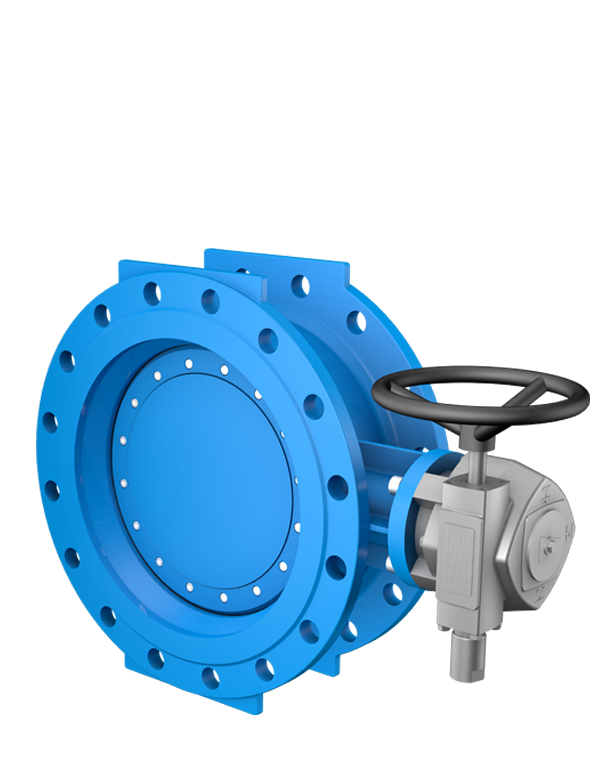

Description

TECHNICAL DETAILS

- Nominal pressure PN 10 / PN 16 / PN 25.

- Nominal diameter DN 150…DN 2000.

- Resilient seated in accordance with EN593

- Face-to-face length acc. to EN 558, basic series 13

- Face-to-face length acc. to EN 558, basic series 14, IS13095-Long/Short face to face option available

- With flange ends on both sides acc. to EN 1092-2

- Body and Disc made of ductile Iron- GGG50/GGG40 as per IS3896(Part2)

- Body and Disc: Epoxy coating with approx. 250 microns – WRAS approved powder

- Stem: Stainless steel SS420/410

- Body Seat: Nickel weld overlay/Stainless steel ring/ SS weld/ Epoxy coated

- Valve Sealing: EPDM

- Bush: Brass/Bronze/SS backed PTFE

- O-rings: NBR/EPDM

- Bolts made of stainless steel A4

- Epoxy coating is food grade approved.

Range of application

- Under the ground/chamber-less/buried installation

- Above the ground Installation

- Chamber Installation/On the pipeline in Plants, Etc.,

On/Off application

PRODUCT DETAILS

Product Features:

- Disc Shape is optimized: for lower zeta value, it helps to have lower head losses,

- Pressure supported sealing system: the hydraulic pressure in the pipeline will help in sealing the seal on to the seat in both directions, this is due to the profiles of the seal which also helps to hold in place even at high flow velocity.

- Double Eccentricity: The valve is a double eccentric design which helps to have compression free seal in the open condition, which helps for longer life of the seal.

- Medium free shaft: Due to O-rings & self-lubricated bearing bushes make the shaft medium free, which provides corrosion protection to the shaft.

- Pin connection: Disc & Shaft are connected by shaft pin so that it provides positive connection without any backlash.

- Weld Seat: The seat weld on the body is by Ni weld overlay which provides wear resistant, corrosion proof, the seating surfaces has smooth finish which increases the longevity of the sealing system.

- Valve Feet: This helps to keep the valve in stable standing position & also it has holes for lifting purpose for higher sizes

Reviews

There are no reviews yet.